1. What is sorbitol?

Sorbitol is non-volatile hexavalent alcohol. It has stable chemical properties, is not easily oxidized by air, is easily soluble in water, and is not easily fermented by various microorganisms. It has a good heat resistance and does not decompose at a high temperature of 200 degrees. Sorbitol is a cool sweetness, the sweetness is 65% of that of sucrose, and the heat is very low. Sorbitol has good hygroscopicity and has a wide range of effects in food, daily chemical, pharmaceutical and other industries. Sorbitol used in food can prevent the food from drying and aging, extend the shelf life of the product, and can effectively prevent the crystallization of sugar and salt in the food, and can maintain the intensity balance of sweet, sour and bitter taste and increase the flavor of the food.

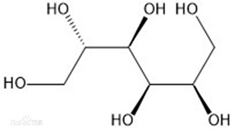

Its other names are D-Glucitol, Sorbol, D-Sorbitol. The chemical formula is C6H14O6, with the molecular weight of 182.17. Its CAS no. is 50-70-4, and the EINECS no. is 200-061-5.

Sorbitol structure :

It totally has three types: sorbitol powder, sorbitol solution non-crystalline (also known as food grade or daily cosmetic grade) and sorbitol solution crystalline (also known as vitamin c grade or pharmaceutical grade).

Sorbitol solution is also called sorbitol syrup, sorbitol 70% solution and sorbitol liquid.

2. Sorbitol manufacturing process

The sorbitol production process uses oral glucose as raw material and undergoes a series of processes such as hydrogenation, reduction, and decolorization and etc. to obtain sorbitol syrup.

Sorbitol syrup manufacturing route:

Reception of grain or roots–> Cleaning of grain or roots–> Disintegrating and wet milling–> Starch extraction–> Starch concentration–> Starch refining–> Starch liquefaction–> Hydrolysate saccharification–> Dextrose purification–> Dextrose concentration–> Dextrose preparation–> Dextrose hydrogenation–> Sorbitol purification–> Sorbitol concentration–> Sorbitol syrup

Sorbitol powder manufacturing process:

Sorbitol syrup–> Preheating material–> Negative vacuum–> More than 99% liquid–> Cooling crystallization–> Dry–> Smash–> Metrological